Blog /

IIoT Drives Sustainability, Safety, Revenues in Energy

The Industrial Internet of Things (IIoT) can empower enterprises to take their operations to new heights, as companies no longer have to choose between sustainability, safety and their bottom line. As prices for hardware and sensors continue to drop, organizations can now cost-effectively add intelligence and connectivity to their industrial infrastructure. Whether collecting new data points from archaic equipment, or monitoring events on a remote site in real-time, companies adopting IIoT can gain an unprecedented level of visibility into their operations by tapping into data from the physical world. This new information, when digested and indexed effectively, also translates into new insights. With the proper IIoT platform, those insights can lead to more informed decision-making and ultimately, predictive maintenance – stopping problems before they start.

Sounds great in theory, but how about in practice?

At Andium, we are an IIoT ecosystem of products and services empowering leaders in the energy industry to implement major sustainability and safety improvements while reducing their operational costs. By integrating cost-effective, easy-to-install hardware with internet connectivity and a common software platform, Andium is providing oil and gas companies with the visibility and tools they need to remotely manage their sites more cost-effectively, reduce their carbon footprint and improve the safety of their workers.

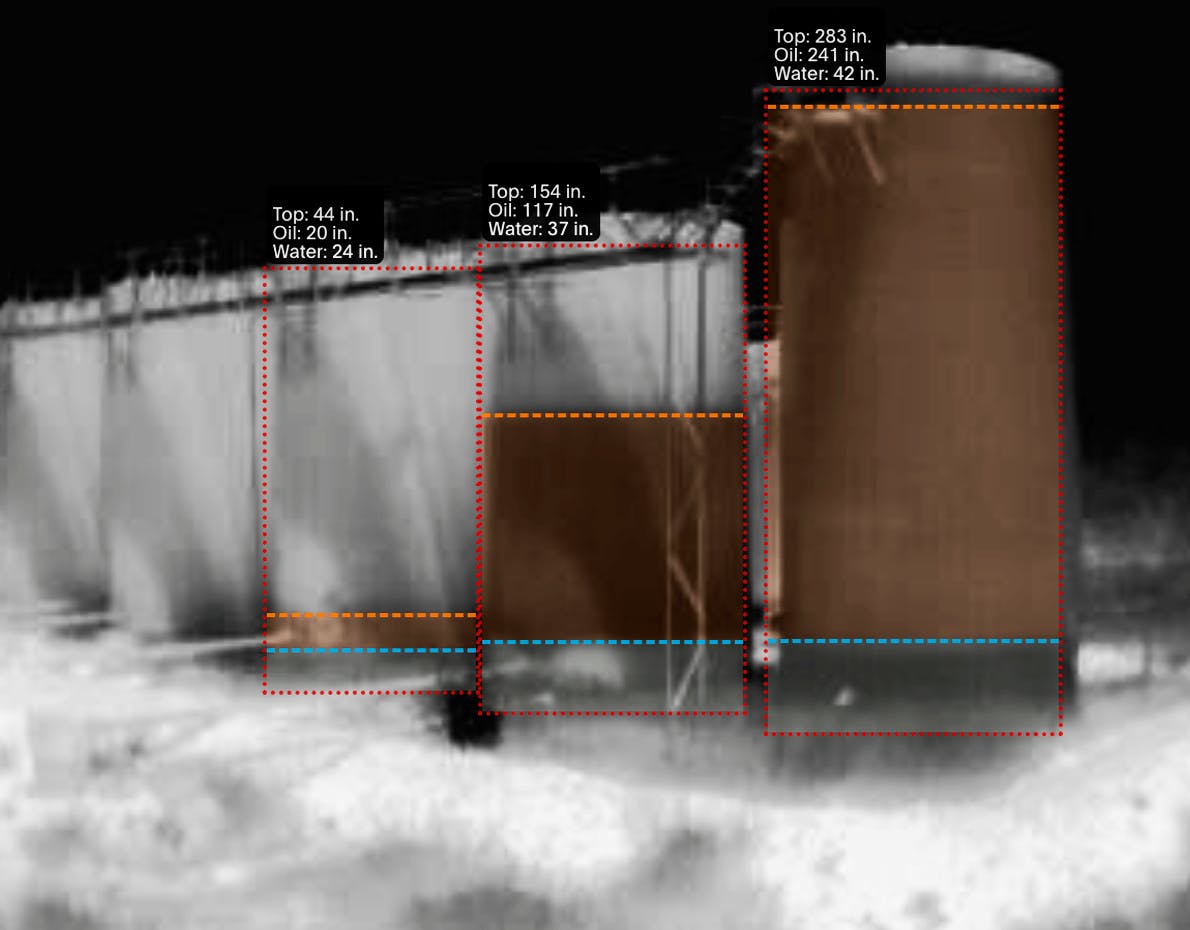

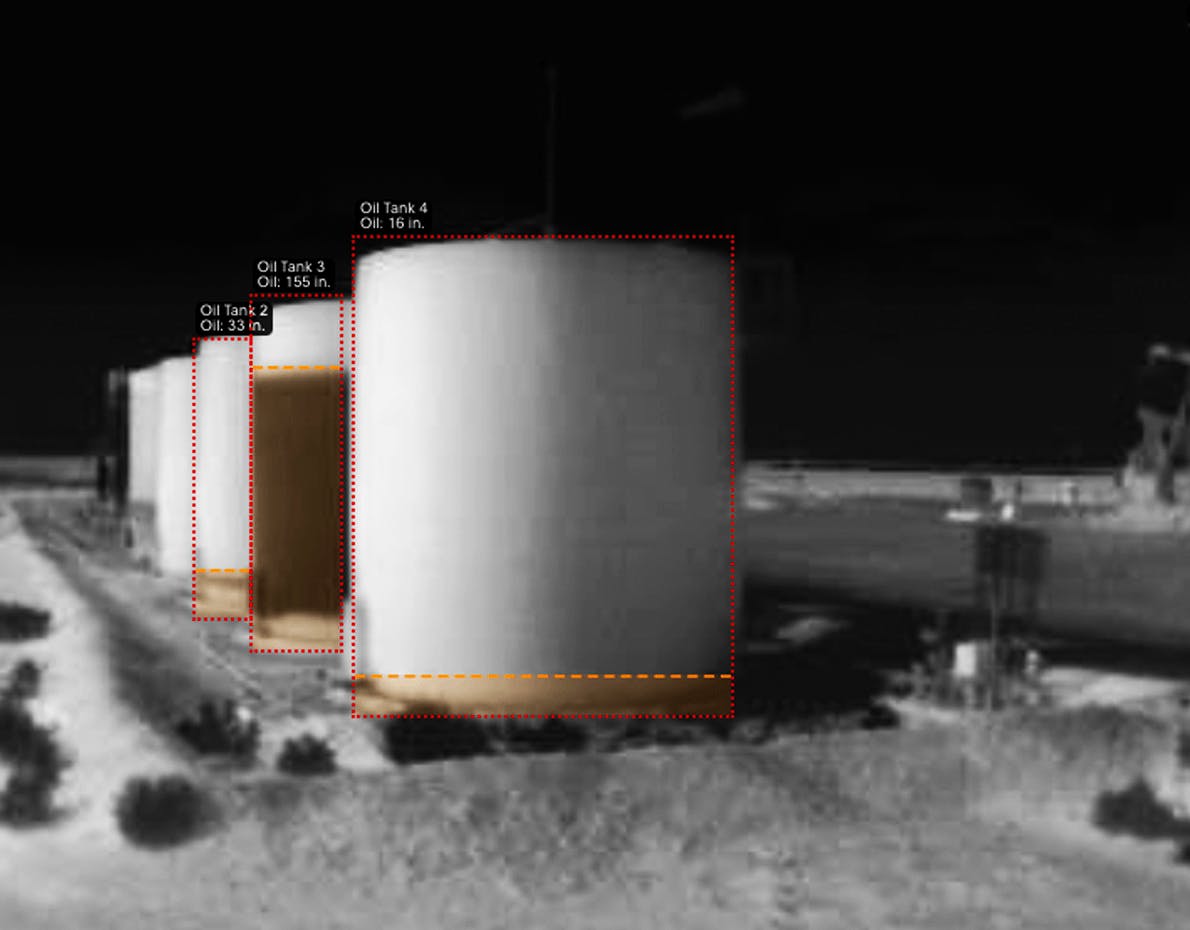

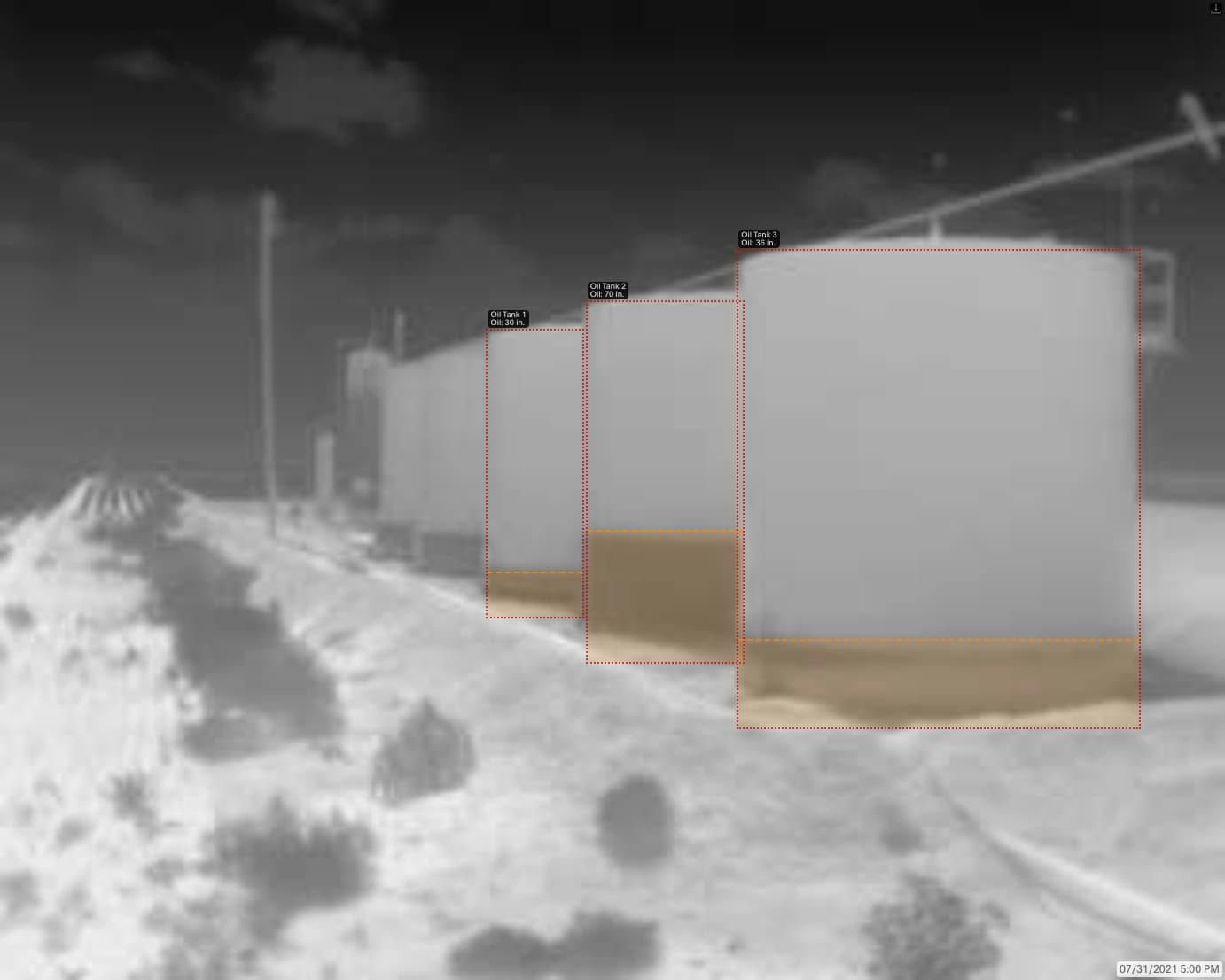

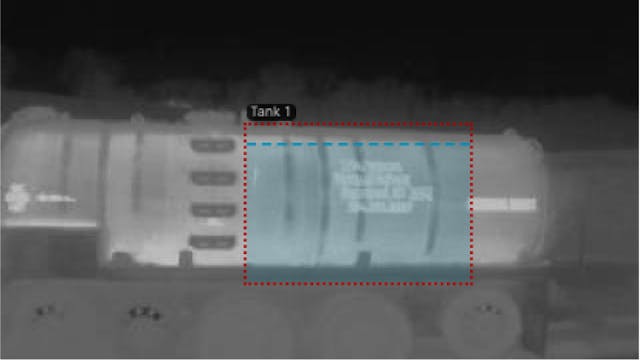

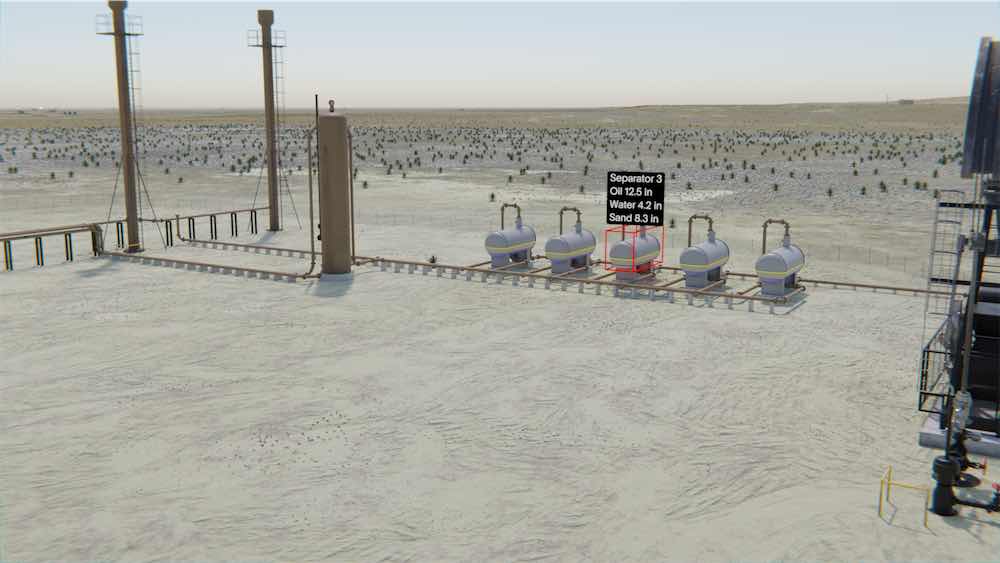

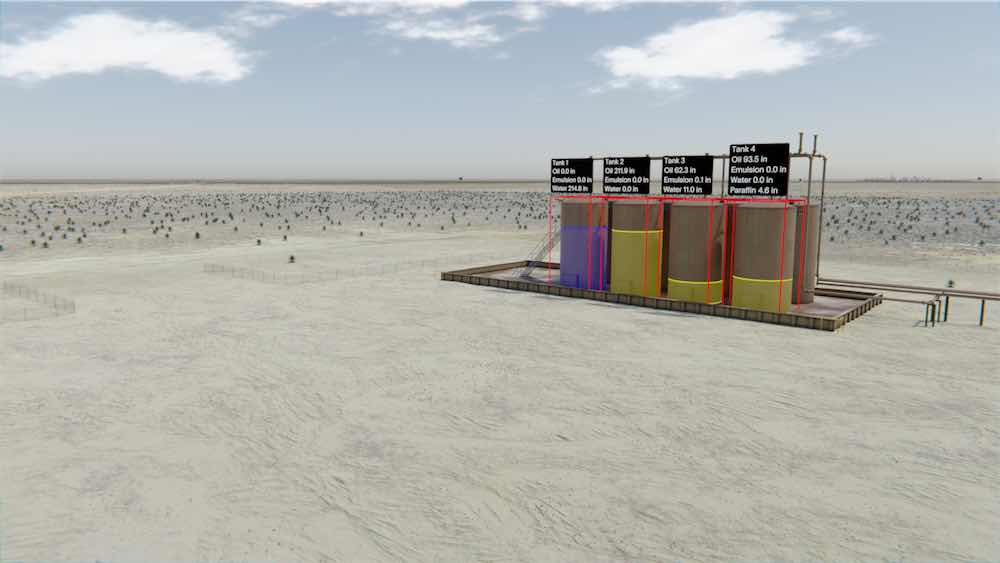

For example, with our smart thermal sensing devices, enterprises in the energy industry can manage oil and water levels across their wellsites without ever touching a tank. Traditionally, oil and gas companies have relied on either manual measurements from field personnel or readings from in-tank measuring equipment for liquid tank levels.

Manual tank gauging is not only time and labor-intensive, it can also be dangerous.

With manual gauging, the work is not only time and labor-intensive; it can also be dangerous. From climbing tanks to potential noxious gas exposure, worker safety hangs in the balance on every site visit. Conversely, due to the lack of continuous monitoring, an unattended site means that a tank overflow could go unnoticed for hours. Even when a company can access in-tank measuring readings remotely, such equipment is often riddled with maintenance needs. With Andium, customers can remotely monitor multiple tanks simultaneously with a single device that sits 50 feet away from any critical equipment. By cutting back on everything from employee driving time to the dangers of onsite work itself, companies can save millions across their supply chain with added efficiencies while also reducing worker accidents.

That’s just the beginning.

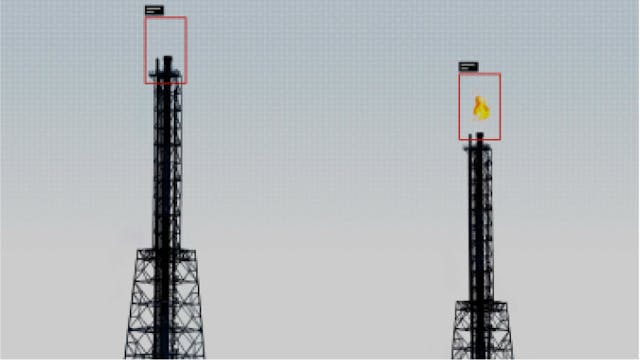

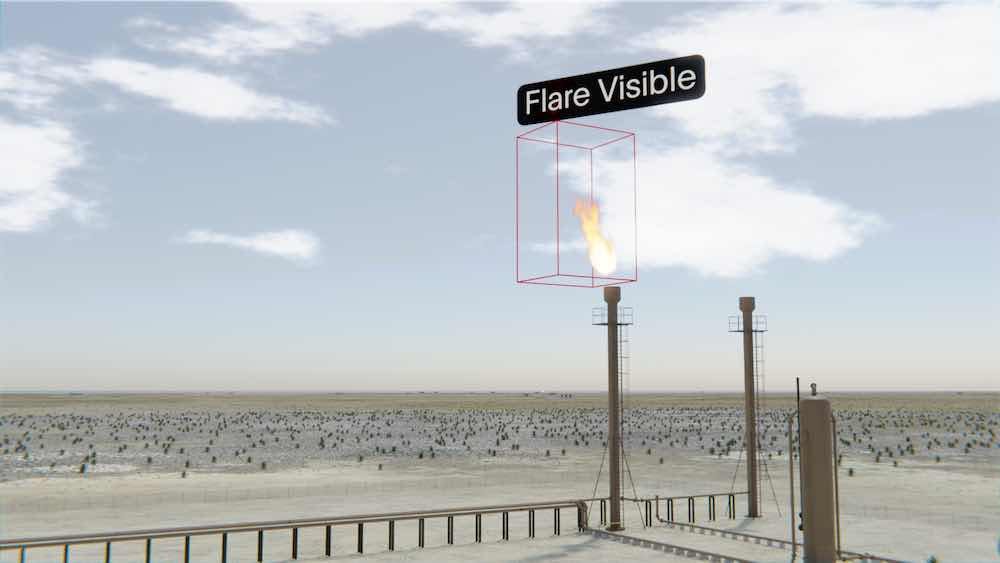

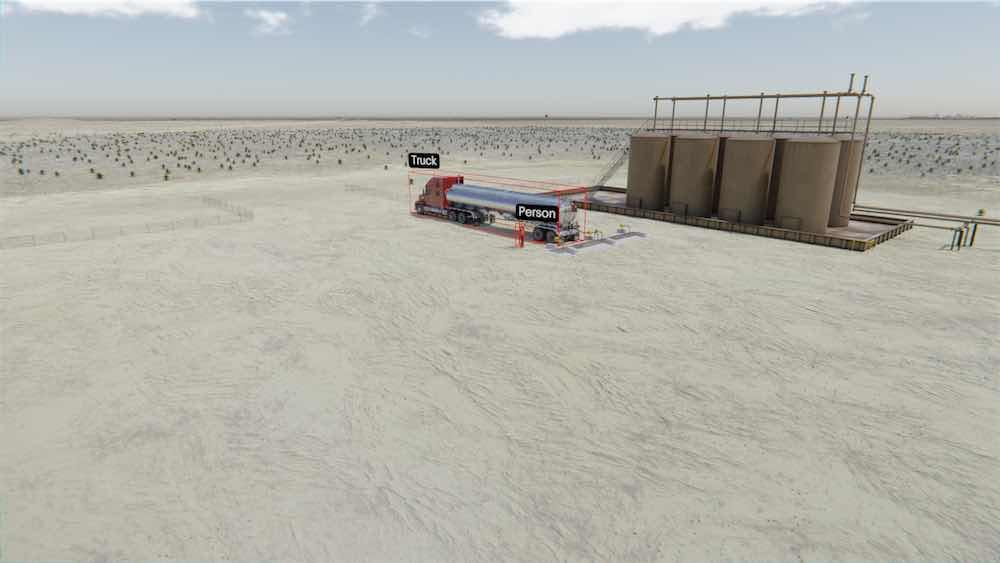

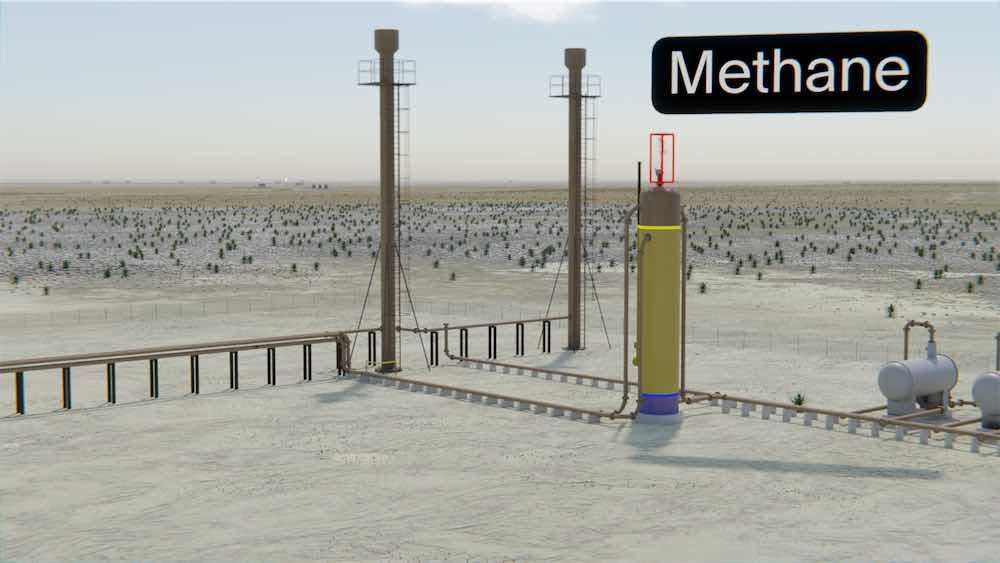

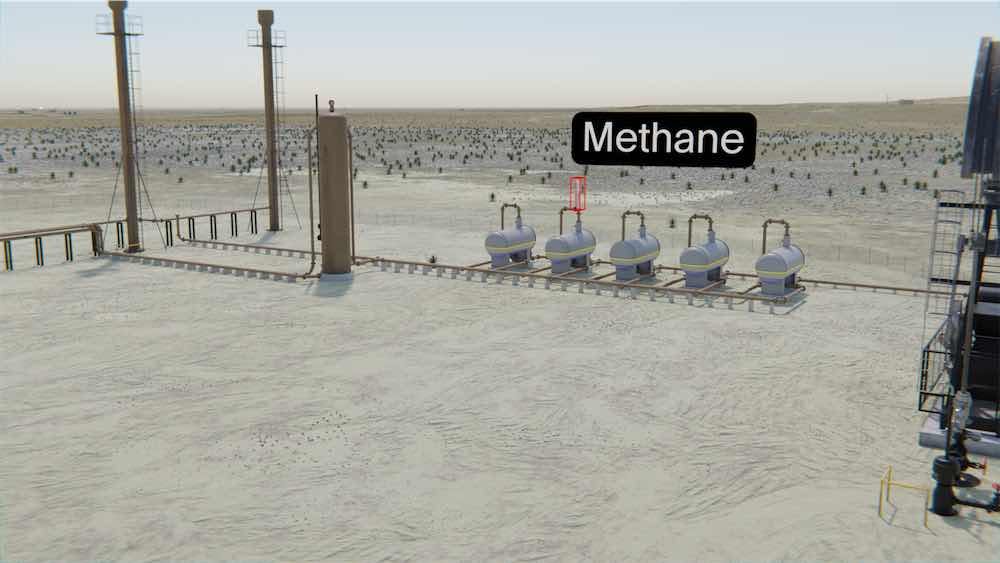

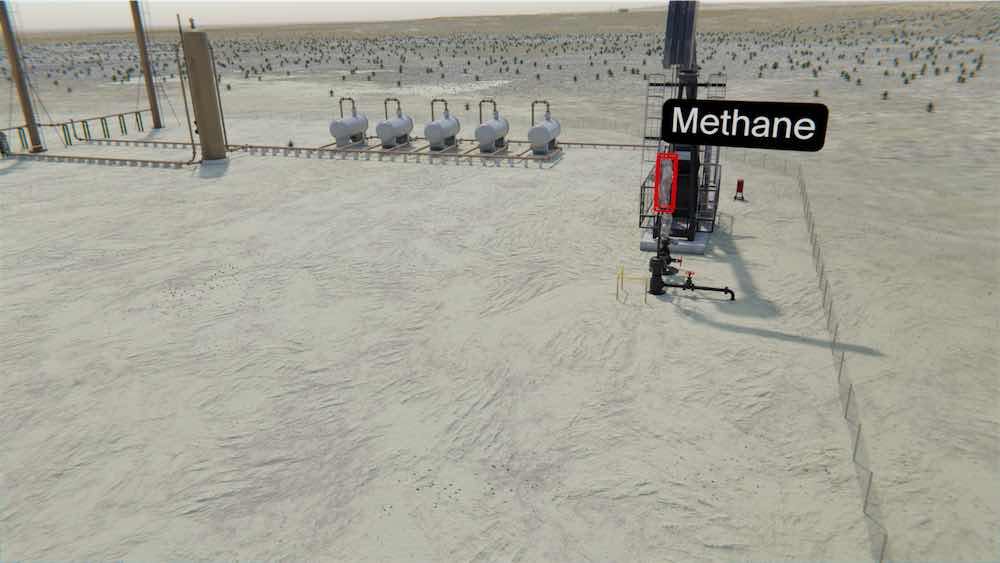

By also incorporating smart optical imaging, our clients are monitoring their remote sites in real-time for other types of accidents, unauthorized personnel, fires or any unintended emissions. For instance, Andium is able to automatically detect if onsite natural gas flaring is emitting black smoke or if a flare’s pilot light goes out, indicating a potential gas leak. Catching such a leak immediately is a game-changer for reducing pollutive emissions.

In general, if a device detects an issue, the system alerts the appropriate personnel instantly so that the customer can address any site problems without delay. Gone are the days of manual site checks or periodic drone flyovers for intermittent and inefficient site monitoring. Other types of low-cost sensors can also identify everything from equipment at risk of failing, to site anomalies, without ever needlessly sending a person onsite and exposing them to unanticipated risks.

The capabilities are all well and good, but when it comes to enhanced site monitoring, the hidden costs of required infrastructure add-ons and change management will often kill an implementation before it even gets off the ground. That’s why we had to do more than make our products effective; we had to make them easy. In less than an hour, a company can have an Andium device installed, activated and monitoring a site without any additional infrastructure or even involving IT. It’s with that type of ease and our clients’ success that has propelled Andium to #200 on the Inc. 5000 fastest growing companies list, working with some of the most influential oil and gas organizations in the world to leverage IIoT to bring meaningful change to the industry.

Sustainability. Safety. Profit.

Energy isn’t the only industry that can start tying these together. Whatever the industry. However old the infrastructure. IIoT is here and when deployed effectively, it is here to make a world of difference for any operation.

Related Resources:

Get a Quote

Reach out for more information and we’ll be in touch soon.