Blog /

A Proven Solution That Will Help Colorado Oil Producers Remain Compliant For SB 19-181

With new Colorado regulations passing, a higher level of emissions monitoring will be needed for oil and gas companies producing oil. Because of this, Colorado oil and gas producers are turning to Andium for smart solutions that have already been proven across Texas, New Mexico, and other states that leverage Andium’s technology.

There are close to one million active oil and gas wells in the United States and Andium believes that most of North America will be remotely monitored and managed by the use of the Industrial Internet of Things (IIoT), to achieve sustainability as well as environmental compliance. With new environmental regulations passing, oil and gas companies are looking for solutions that not only mitigate fugitive emissions, but also achieve more sustainability. Andium, a company named the 200th fastest-growing private company in 2020 has been on the forefront for years of this digital transformation and has provided solutions that replaces manual tank gauging to enhance operational efficiency, safety and regulatory compliance.

Tank Level and Emissions Monitoring

Traditionally, oil and gas companies have used two main methods to conduct fluid management while producing oil from beneath the surface. One method is the use of guided wave radar sensors. Not only is the use of guided wave radar sensors expensive – costing thousands of dollars per tank, but it also involves opening the “thief hatch” at the top of the tank. Opening the thief hatch of an oil tank emits a large volume of volatile organic compounds (VOC), which damages the environment and raises safety concerns for workers. Fatalities have been reported on wellsites due to fugitive emissions being released while manually gauging an oil tank or during standard maintenance. In the state of Colorado, Senate Bill 19-181 (SB 19-181) prohibits the opening of thief hatches for the above reasons. This is why non-invasive solutions will now be needed for oil and gas companies to effectively continue producing oil.

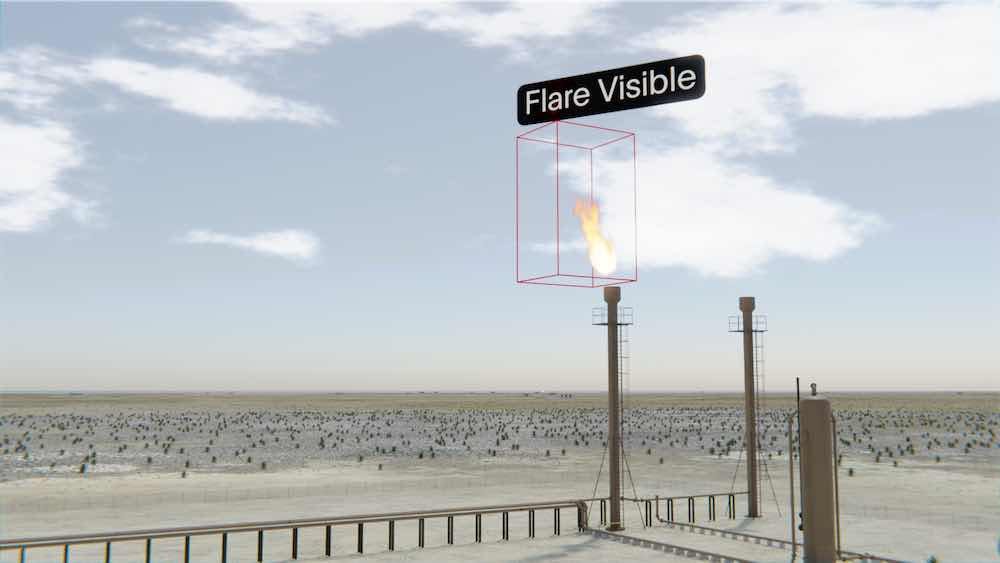

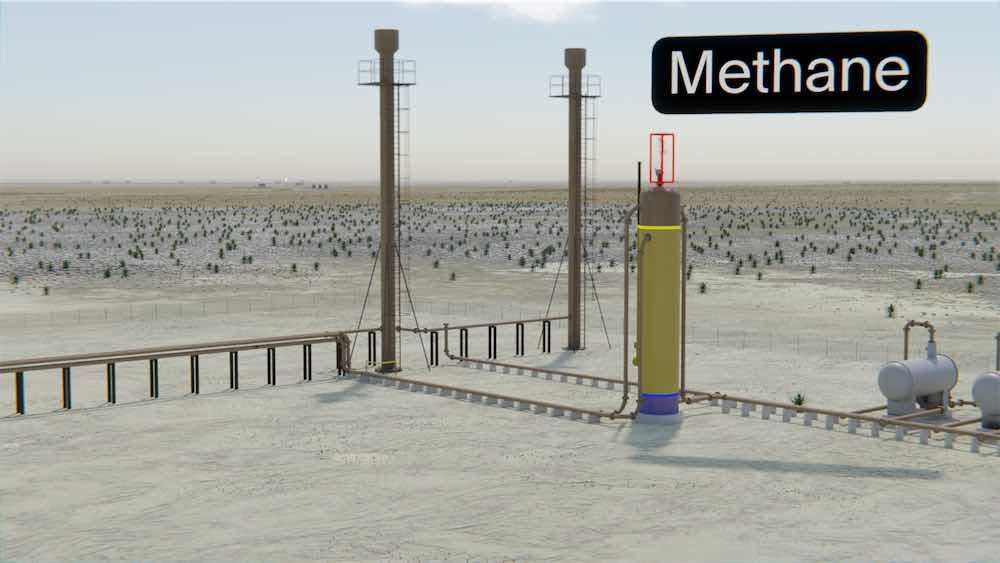

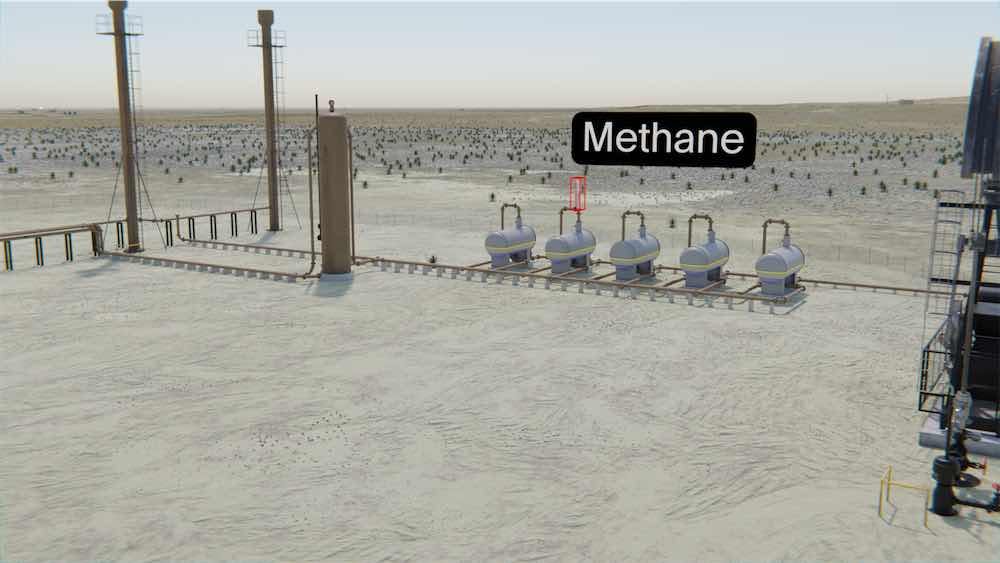

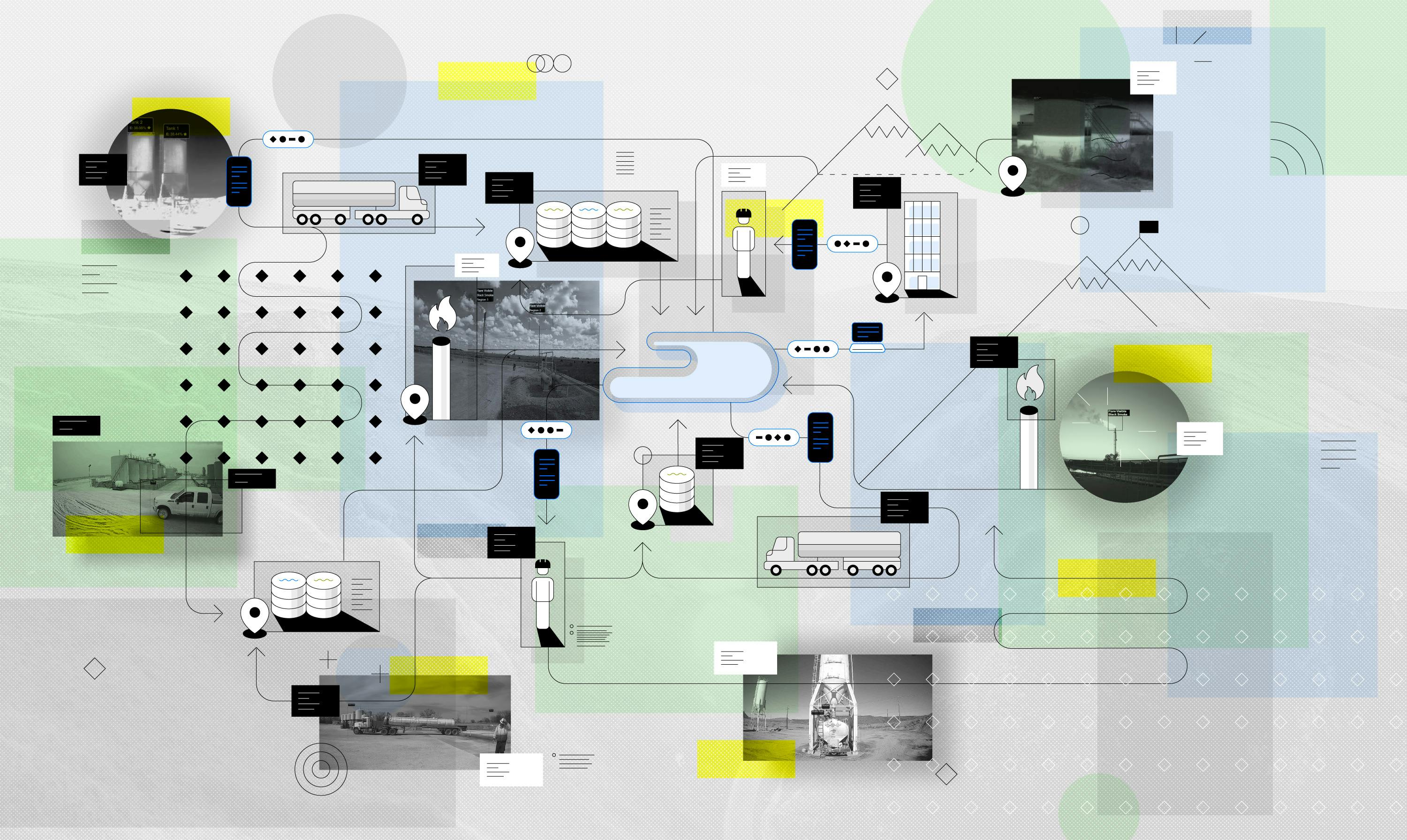

Colorado SB 19-181 regulation also mandates the requirement of real-time gas emissions monitoring. Today, oil and gas producers deploy leak detection teams to inspect for leaks, but this solution is inefficient and doesn’t employ real-time monitoring. Not only is it laborious, but there are hundreds of items to inspect across thousands of locations. The only sustainable way of achieving efficient and accurate emission monitoring is through the use of an IIoT platform that utilizes artificial intelligence and machine learning.

A Proven Method

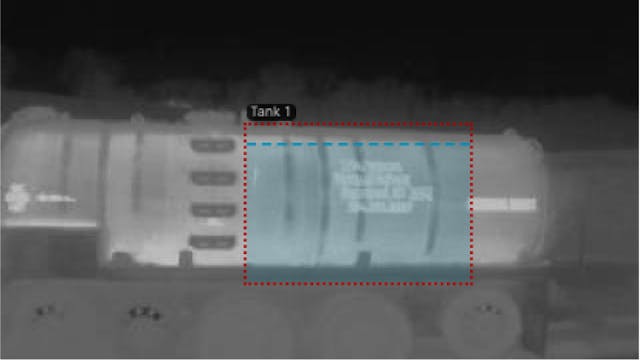

For years, Andium has been quietly impacting the energy industry one company at a time. They were the first to create and successfully implement a thermal imaging solution for safe, cost-effective tank-level management that has saved their clients millions at scale. After seeing much success in Texas, the heart of American oil and gas production, Andium implemented their technology in other states.

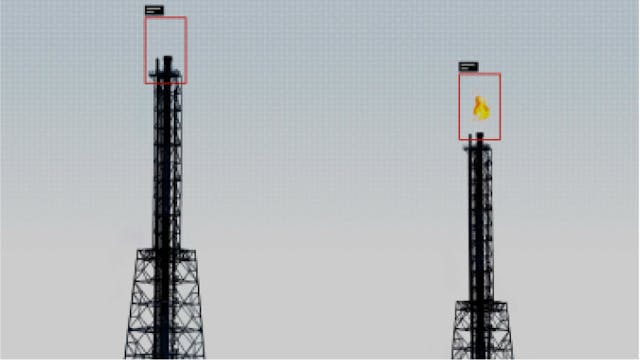

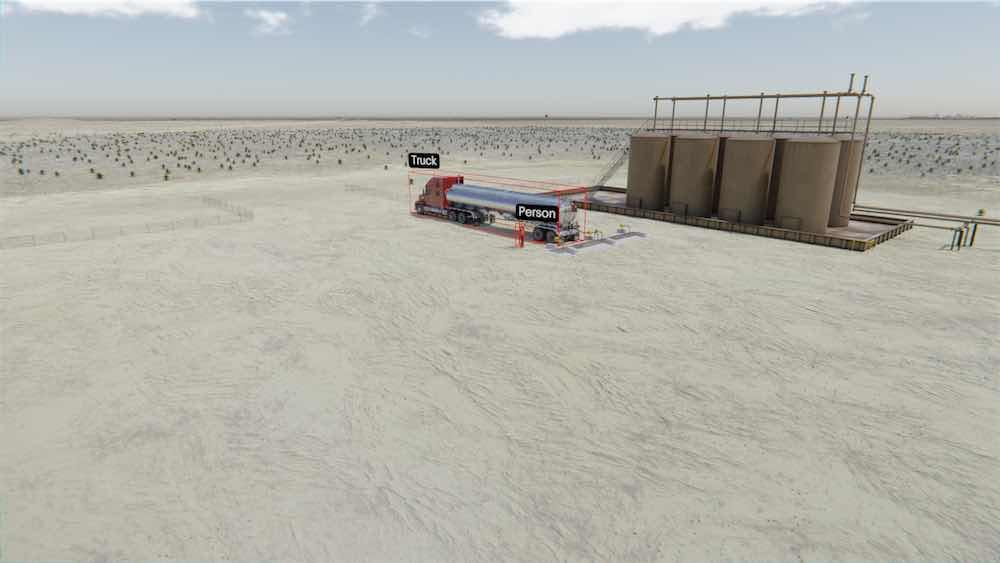

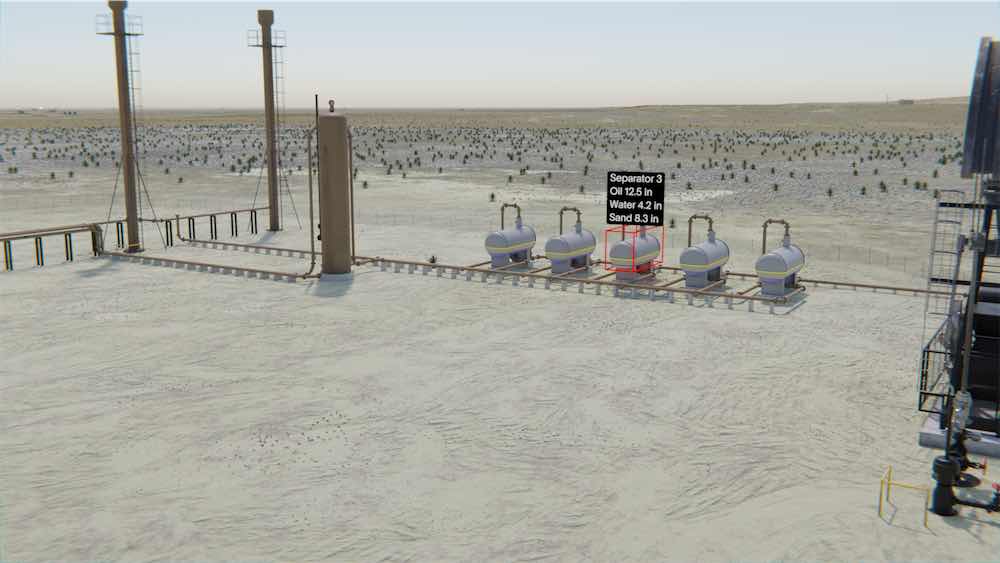

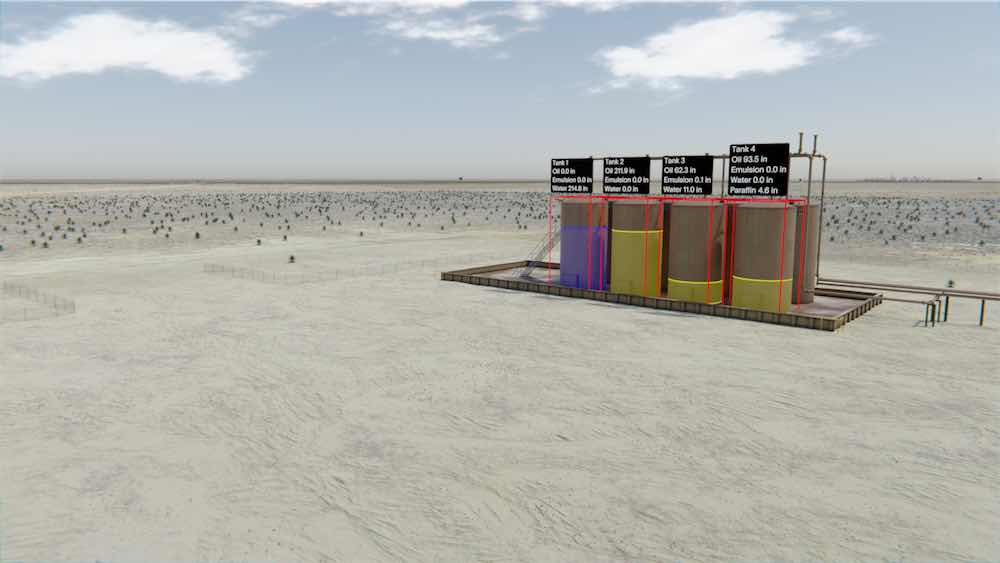

In Texas, companies were eager to implement the new technology and installed over one thousand devices to assist with wellsite management. The devices monitored wellsite assets without the need of replacing any existing hardware. The devices ranged from thermal cameras that measured oil, water, and emulsion levels within above-ground storage tanks, to flare and emissions detection devices with site security. Andium provided oil and gas producers with a plethora of new insights and efficiencies leading up to predictive maintenance.

In Colorado, oil and gas companies can face substantial fines and operational closures if they are not able to meet Colorado’s SB 19-181 standards. With Andium’s IIoT ecosystem, oil and gas producers will not only remain within compliance of regulatory standards but will also achieve a new level of sustainability.

Results

Andium’s ecosystem saved oil and gas producers millions of dollars annually across their supply chain and can potentially save oil producers an additional six to seven figures in fines when implemented in Colorado. With the ability to accurately and cost effectively monitor wellsites twenty-four seven, oil and gas companies can now work towards a sustainable future, preventing future environmental damage with predictive maintenance and change the public perception of the oil and gas industry.

Related Resources:

Get a Quote

Reach out for more information and we’ll be in touch soon.