Blog /

Ensuring Your Pilot Lights Always Work

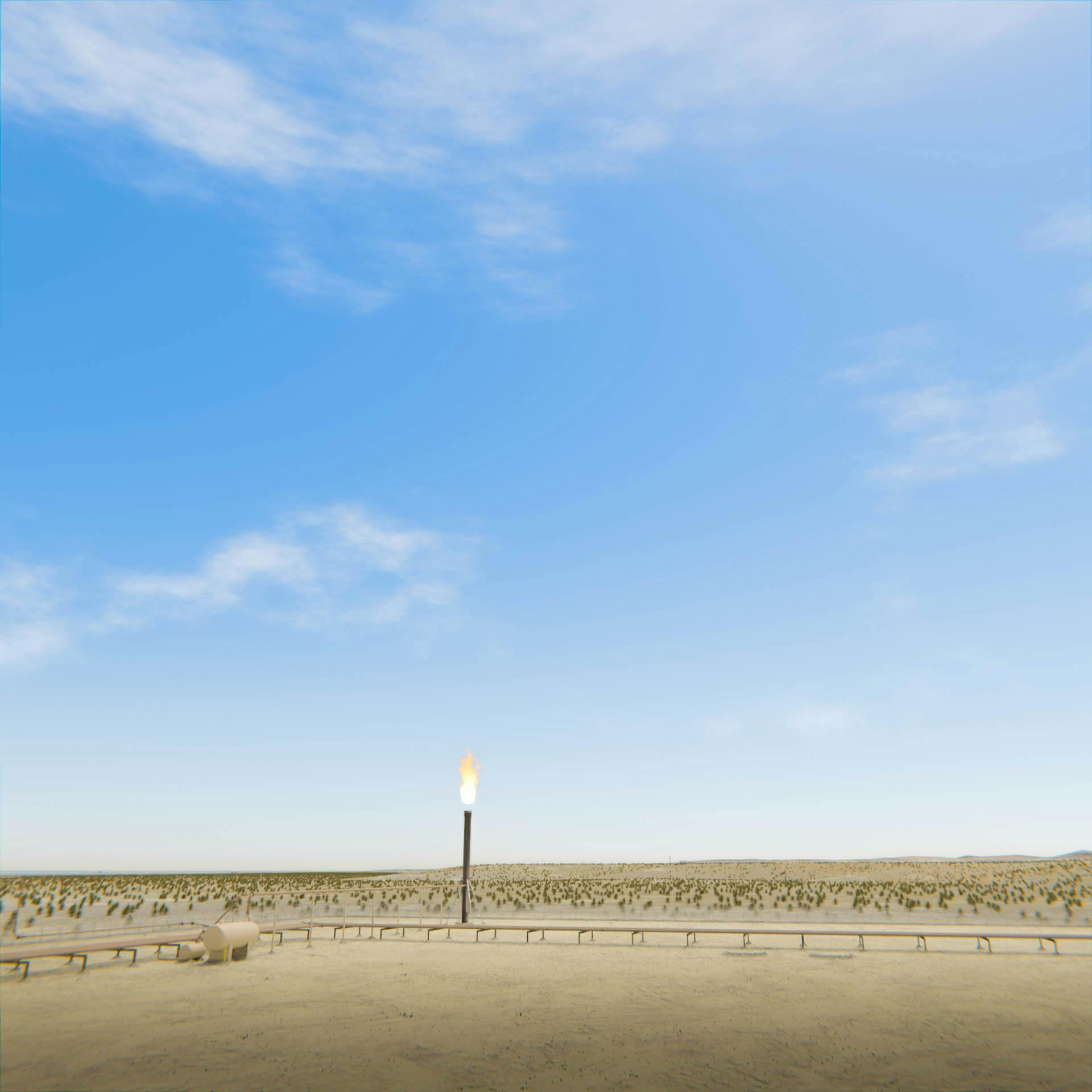

A reliable pilot light monitoring system is crucial. It alerts you right away if a pilot flame outage occurs. You need the appropriate equipment to monitor your flare stacks and ensure they function properly. The leading monitoring equipment will help save you money and keep you compliant with regulations.

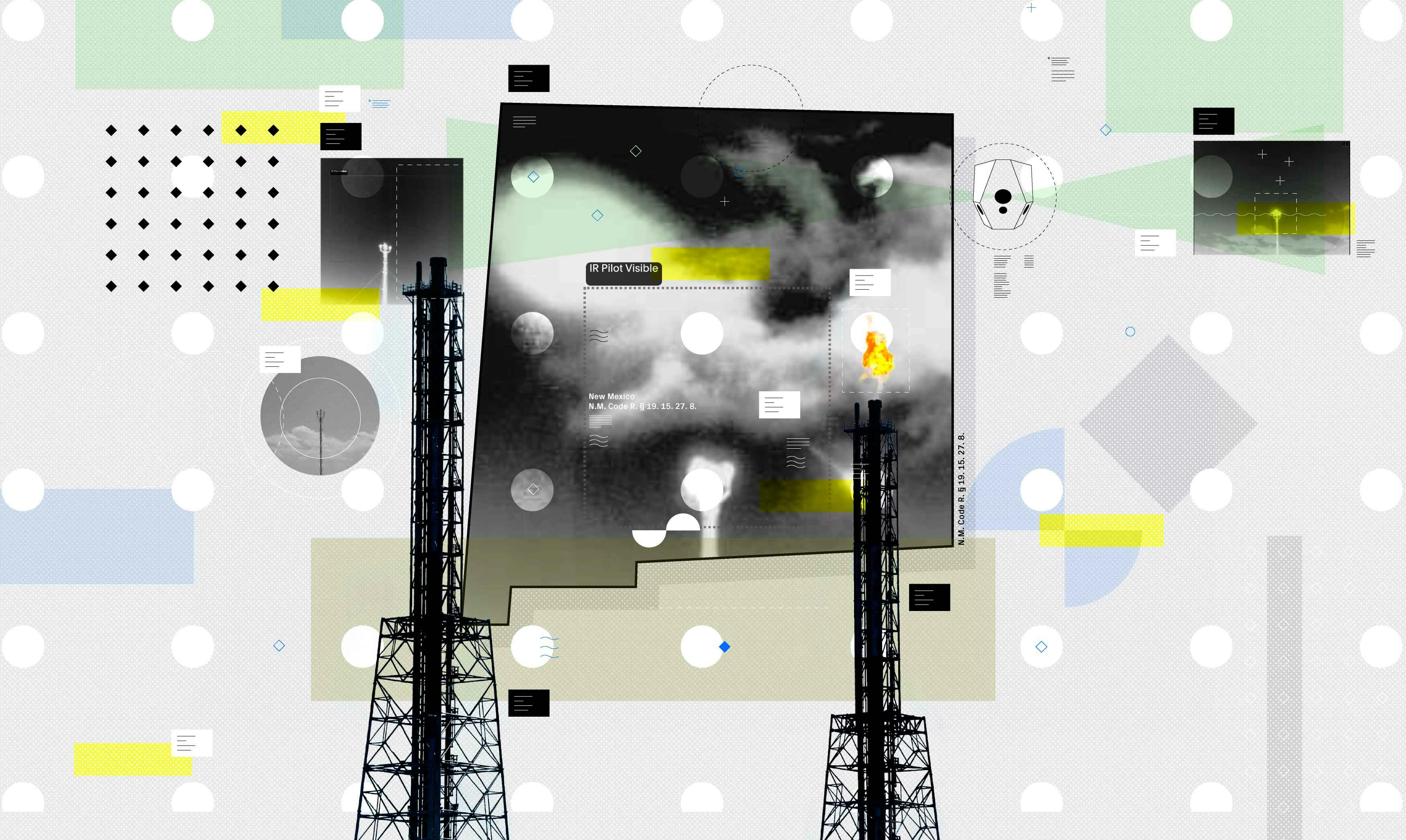

Strict state and federal regulations are going into effect across the United States aiming to reduce fugitive emissions. One such regulation is N.M. Code R. § 19. 15. 27. 8.N.M. It states that "a flare stack installed before May 25, 2021, shall be retrofitted with an automatic ignitor, continuous pilot, or technology that alerts the operator that the flare may have malfunctioned no later than 18 months after May 25, 2021."

If you manage flare stacks in New Mexico, you will need to have a pilot light monitoring system within a few months. If you don’t, you could not only face heavy fines but the facility in violation of the regulations will be shut in.

There are several ways to monitor your pilot lights. Some of these methods need to be replaced often. They force you to shut down your location to install intrusive hardware. Others require staff to constantly watch your sites. With the right equipment you can avoid these costly and frustrating obstacles. Let’s look at the methods to track pilot lights.

Thermocouples

Thermocouples are one of the most common methods to monitor pilot lights. If you use thermocouples, you may have noticed some drawbacks. Thermocouples are prone to failure due to their corrosive conditions. As they must be near the flame of the flare stack, thermocouples fail frequently and can be difficult to replace. They also must be deployed in great numbers. You will need a thermocouple for each flare stack at each location, which can quickly become expensive. Many operators still need to manually check these devices to ensure they are functioning correctly, which demands more labor hours spent on something that should be automated.

Regarding replacement, you will probably need a process shutdown for more extensive facilities to remove and reinstall a new thermocouple which is both hazardous to your staff and expensive. This cycle repeats itself over and over again for each thermocouple you use.

Ultraviolet Sensors

Ultraviolet (UV) sensors often monitor flames inside of furnaces. They are less effective at pilot light monitoring on flare stacks.

UV sensors can easily detect UV energy from other sources. These sources include reflected sunlight, gas combinations from existing equipment at your locations, and more. A UV sensor will need to be located close to a flare stack to minimize false alarms.

Staff must monitor these sensors closely to watch for problems. There are better methods for detecting pilot lights.

Infrared Devices

Infrared devices are one of the latest methods to monitor pilot lights. These sensors can detect infrared light from a pilot flame. Infrared devices do not need to be mounted on a flare stack like thermocouples. You will not need to worry about a corrosive environment for your devices or shutting down your process to install this equipment.

These devices can be farther away from flare stacks than UV sensors. Infrared is also much more accurate at detecting the pilot flame than UV. Infrared devices are easily one of the best methods for detecting pilot light outages, but what separates one company’s infrared device from another?

The Andium Difference

Andium Flare Monitoring combines infrared technology with cutting-edge automation. Andium system detect pilot lights for multiple flare stacks. Our automation ensures you always stay informed. You will receive an alert whenever a pilot flame goes out. You can also use the devices to fully automate your Method 22 reporting.

Our technology does the monitoring for you. This frees you to focus on more operationally critical tasks. You’ll be secure knowing that Andium is always watching and ready to alert you the moment something goes wrong.

Get a Quote

Reach out for more information and we’ll be in touch soon.