Blog /

Helping to Fill the Labor Gap in the Oil and Gas Industry

How Did The Labor Shortage Begin?

Several reasons factor into this growing labor shortage. One of the most significant is the retirement of the Baby Boomers, who were born between 1946 and 1964. For decades they were the largest generation in American history, only recently surpassed in size by the Millennials. The Boomer retirement wave began in 2011 and will continue through 2030. In addition, the COVID-19 pandemic has accelerated this cohort’s retirement rate.

With around a fifth of current oil and gas workers over the age of 55, a wide swath of critical roles will be vacant as the Boomers retire. Unfortunately, such roles will have to be filled with less experienced workers. Many positions will have no qualified candidates to fill them at all.

Hiring for the oil and gas industry also has its challenges. Skilled workers are becoming difficult to find as industry majors raise wages to attract the best talent. Companies also need to position themselves to appeal to young professionals. Many of the younger cohort have moved away from the mission and values of the oil and gas sector. More and more, these critical employees flock to the renewables sector. Right when the industry needs a new generation to step up and fill the labor gap, those workers are seeking employment somewhere else.

So what can be done?

Automation in The Oil and Gas Industry

Industrial Internet of Things (IIoT) technology can make up for the shortage of skilled workers. IIoT, coupled with machine learning and automation, makes the oil and gas industry more efficient. Energy companies can use IIoT technology to increase their production, all with fewer employees.

IIoT technology helps staff work from their office, removing the daily costs associated with traveling to remote locations. Workers can conduct site inspections from afar and identify malfunctioning equipment. Field technicians travel to a site only when needed. Companies that use IIoT technology find they operate by exception. They deploy operators to focus on problematic wells and spend no time on locations within compliance.

This automation is also economical for oil rig crews. Flying workers to and from off-shore rigs can cost several thousands of dollars per trip. IIoT continuous monitoring technology watches equipment in place of workers. This technology alerts companies to anything that needs attention, saving, time, effort, and money. Operators fly out crews only when they need to fix a problem.

How Andium Helps the Oil and Gas Industry

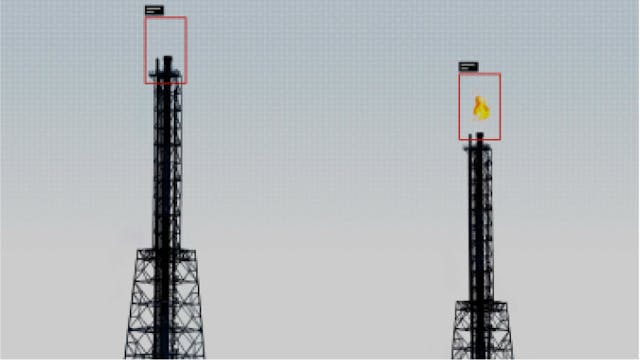

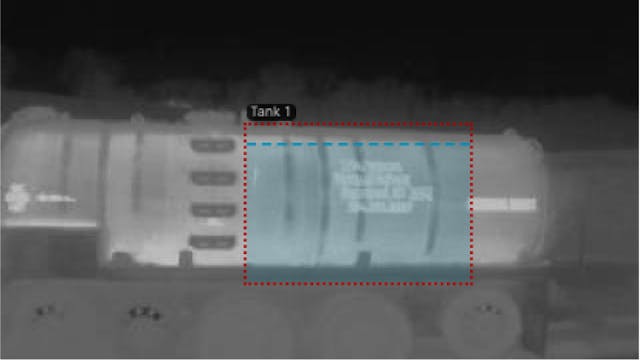

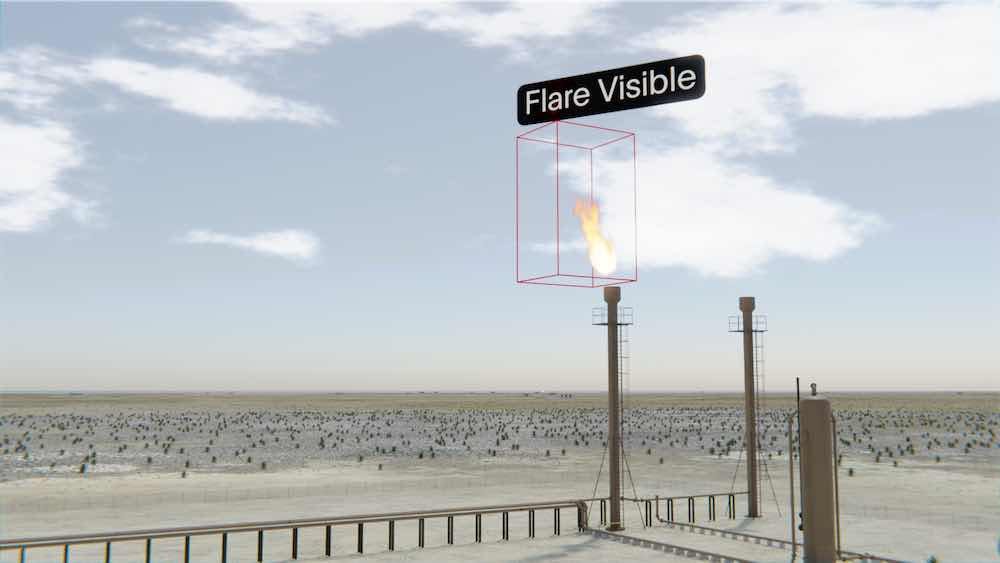

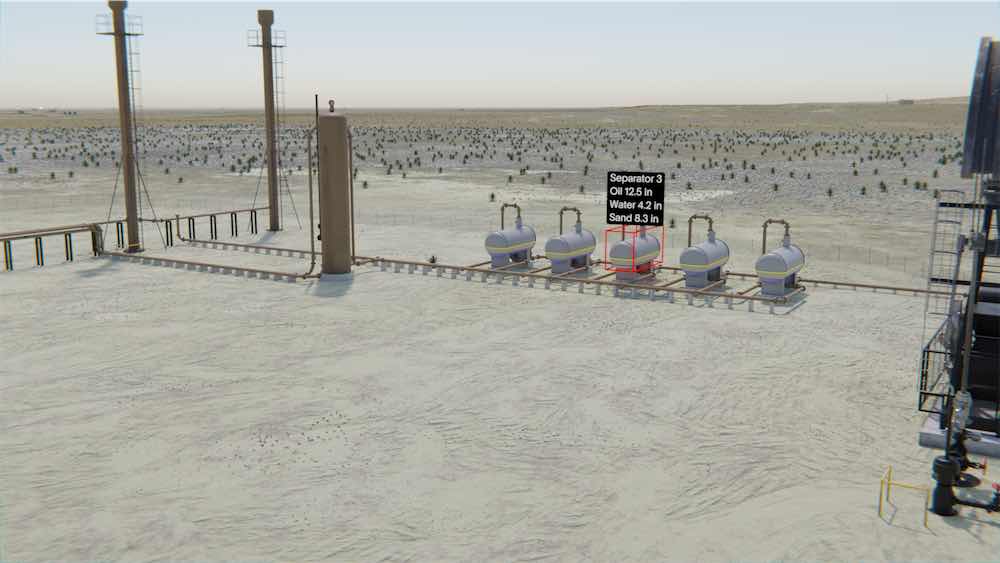

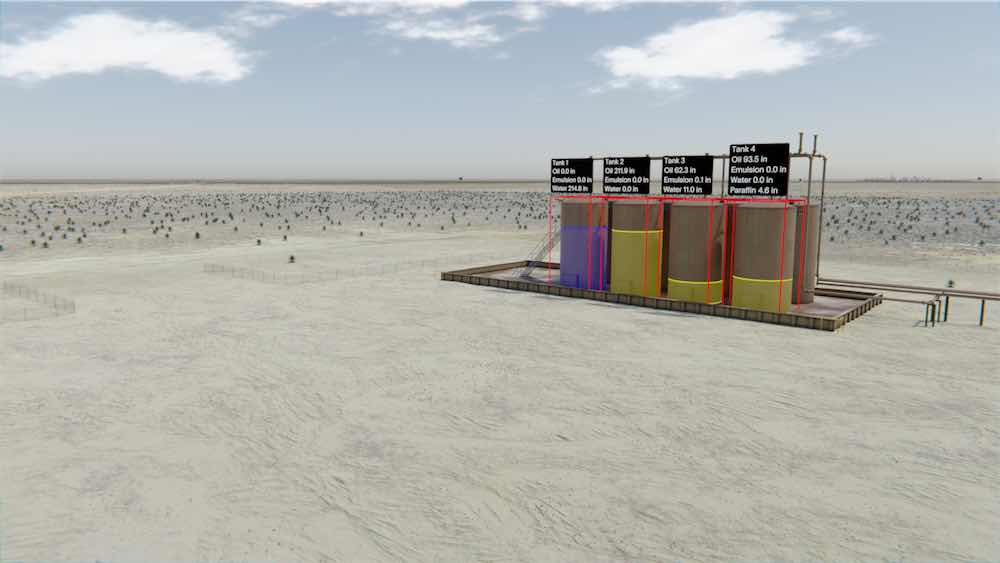

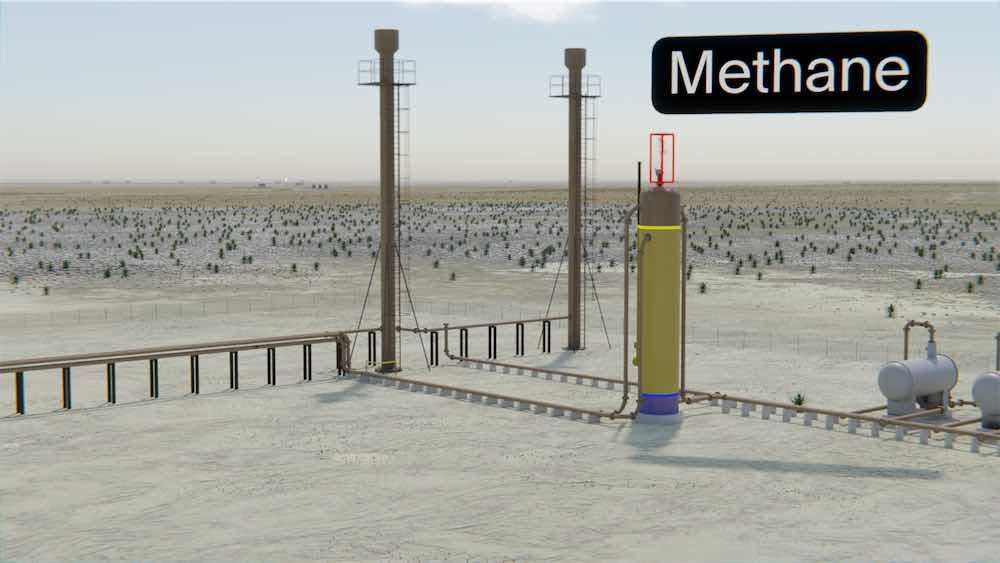

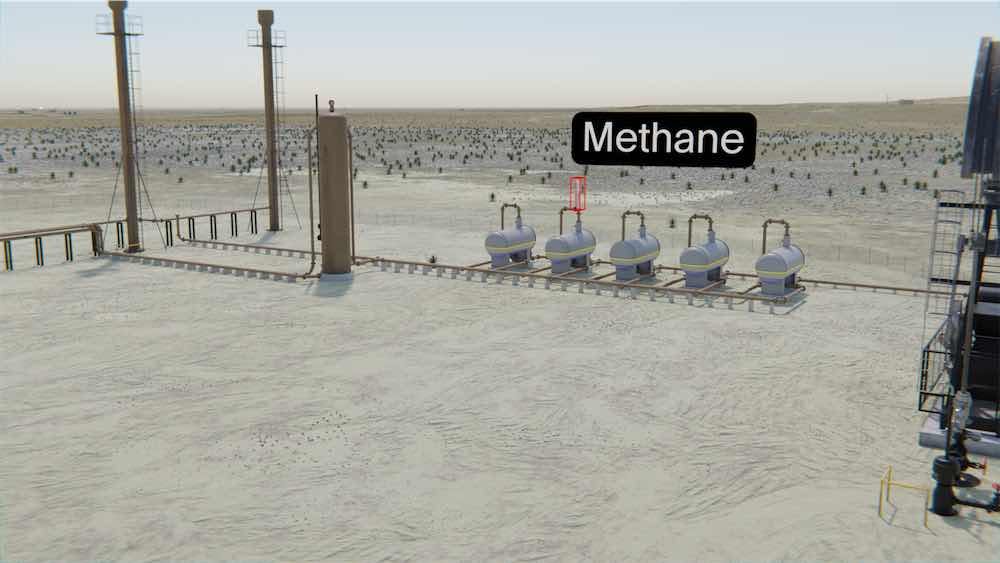

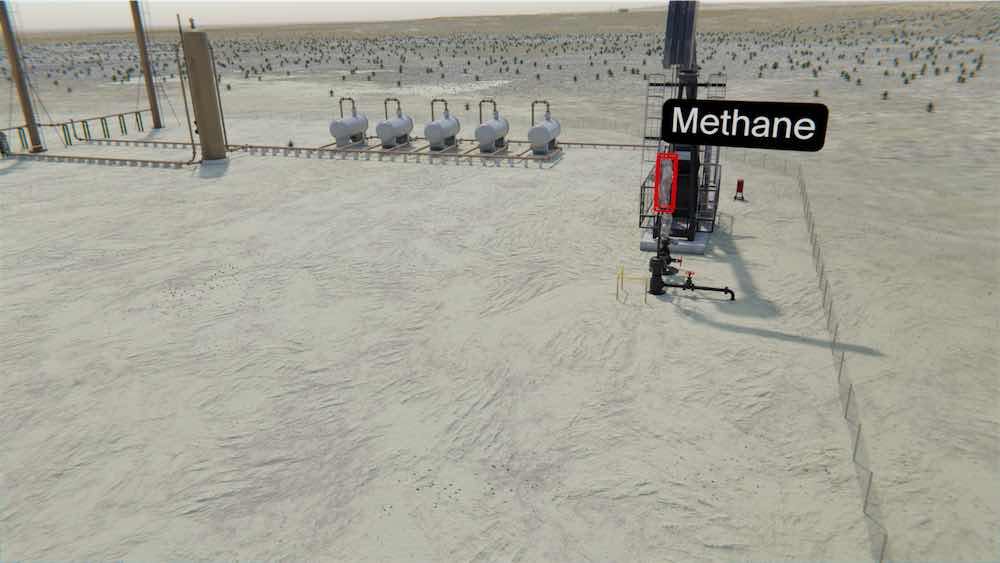

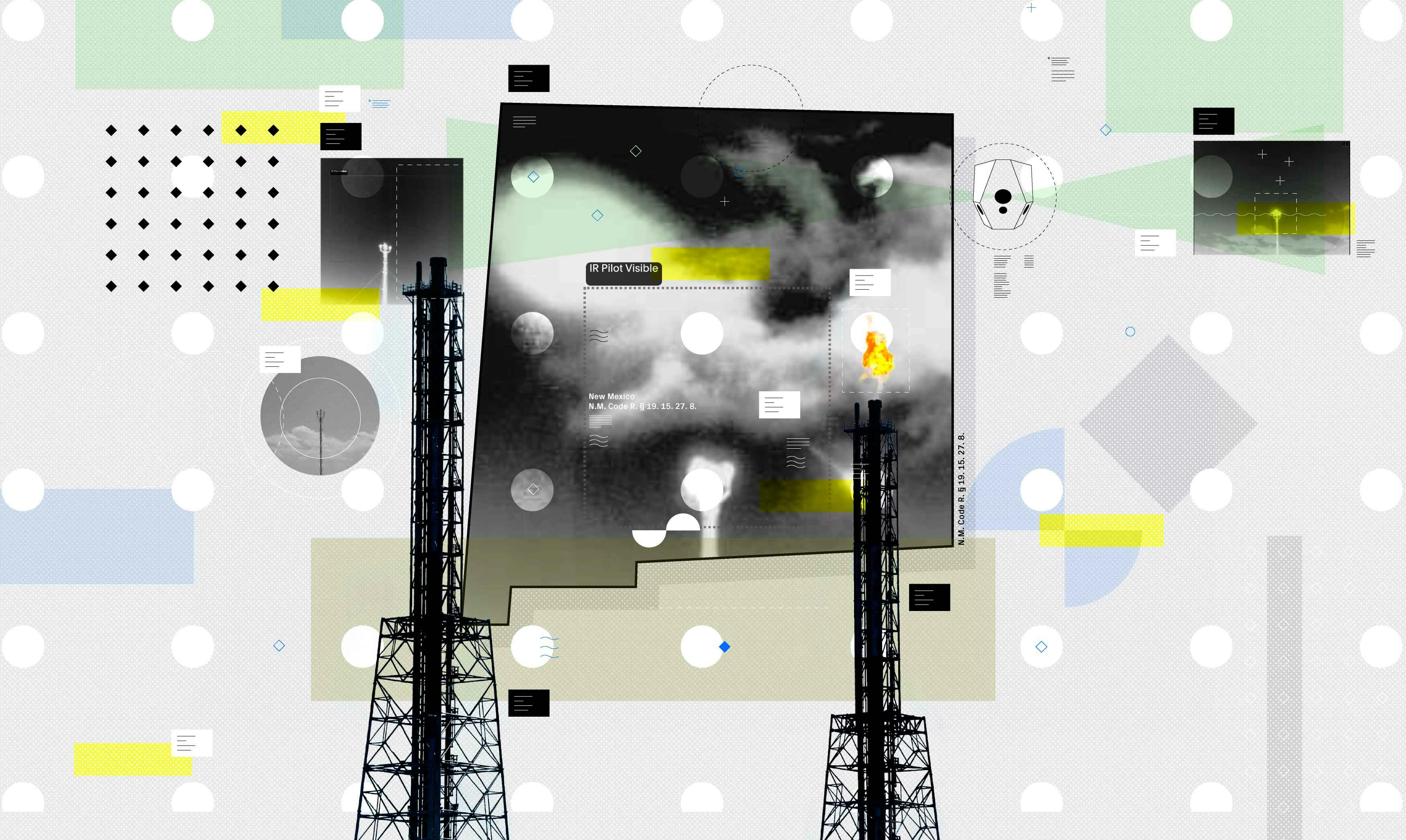

The oil and gas industry still relies on labor-heavy tasks, such as manual gauging for oil levels and manual inspections of onsite equipment. With the industry facing a labor shortage, leading oil and gas companies use Andium to monitor onsite equipment for them. For example, whenever a storage tank vents methane from a thief hatch or a valve, Andium detects the event and alerts the operators within minutes. Andium’s continuous monitoring also watches for pilot light outages, black smoke emissions, and more. Method 22 inspections become fully automated and its reports are sent directly to the user.

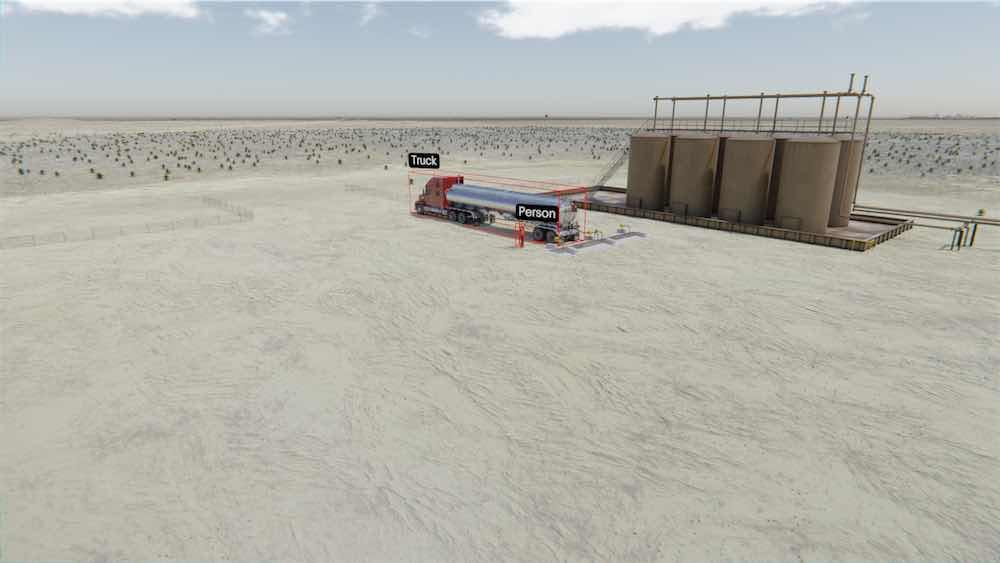

Andium technology helps to increase efficiency and drive sustainability. Our continuous monitoring devices can detect vehicles, personnel, smoking flare stacks, and gasses, such as methane. Andium equipment also watches for onsite anomalies, such as liquid leaks and fires. Companies using these devices can monitor their tanks from outside the tank and keep their thief hatches closed. Users access a dashboard from anywhere in the world and see the status of all their tanks and sites. 24/7 monitoring gives operators the data they need to make informed decisions, all without a single site visit.

Does the Industry Embrace New Technology?

Most of the oil and gas infrastructure dates back to the 1960s. Much hasn’t changed. Only in the last few years has the industry sought new technology to help increase efficiency.

There are a few challenges to adopting new technology. Most oil pads are located in remote areas connected by hazardous roads in uncertain conditions. Oil pads often lack internet connectivity. The outdoor environment can be harsh for untested equipment.

The industry also lacks IT talent. According to JBKnowlege, IT staff was the most limiting factor affecting the adoption of new technology by 36.8% of respondents in 2014 and 39.1% in 2017.

Due to the lack of IT support, it has been common for oil and gas companies to shy away from new technology. This is why Andium makes the process as simple as possible. Our technology can fully integrate with a user’s SCADA system. Andium provides an ongoing partnership with users, who can call on our internal IT team for all the support they need. Our equipment is tough, field tested, and accurate in the harsh conditions often found at oil and gas sites.

The labor shortage does not have to mean a capability shortage. Continuous monitoring IIoT technology is a solution that works. By using monitoring devices to conduct inspections and watch remote locations around the clock, your staff can focus on your most critical tasks. Your team will have the bandwidth to produce more while the demand is still high. Andium will help you meet the world’s rising energy demands and insulate you from the oncoming retirement wave. While others struggle to fill talent gaps, you will be able to do more than ever before.

Related Resources:

Get a Quote

Reach out for more information and we’ll be in touch soon.